How We Support Aerospace and

Defense OEMs

A customized approach to

meet your unique needs and

regulations

We Know How to Help

Electro-Mechanical and Electronics

Manufacturing Expertise

From in-flight entertainment devices for commercial aerospace to military-grade defense electronics to components for the Mars Rover and equipment used to resupply the space station, PARPRO has extensive experience in manufacturing aerospace and defense electronic assemblies.

Our focus and commitment is structured to support the intricacies and demands specific to the aerospace and defense industry. We have been providing integrated subsystems, PCBA’s, rugged enclosures, along with cable assemblies and wire harnesses for over 20 years.

Our Expertise

Complete, turnkey electro-mechanical manufacturing for new product introduction,

high volume production of existing products, and everything in between.

ITAR Registered

An ITAR-registered company, PARPRO is equipped to support defense-related projects across the United States.

Customized Solutions

Decades of Experience

With over 20 years serving the aerospace and defense industry, PARPRO's focus, and commitment is structured to support the intricacies specific to this industry.

Manufacturing Capabilities

Innovative solutions designed to meet your needs

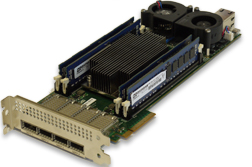

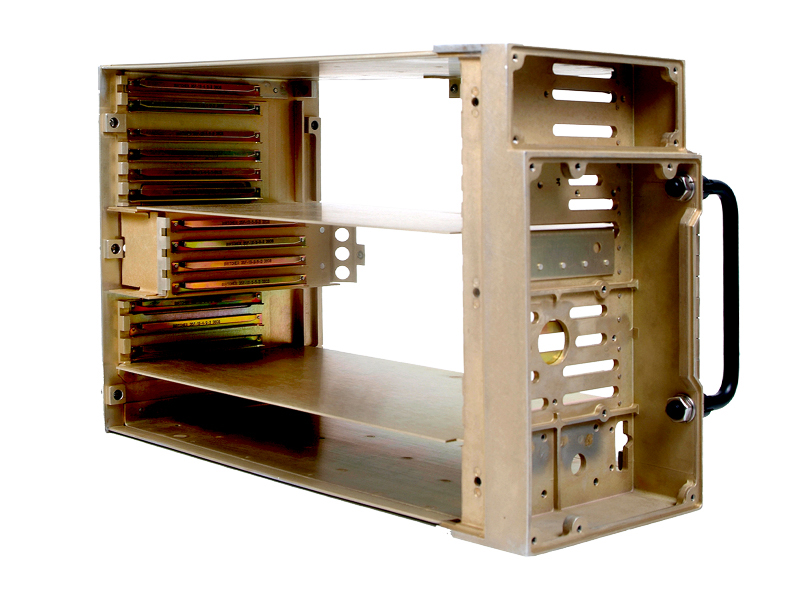

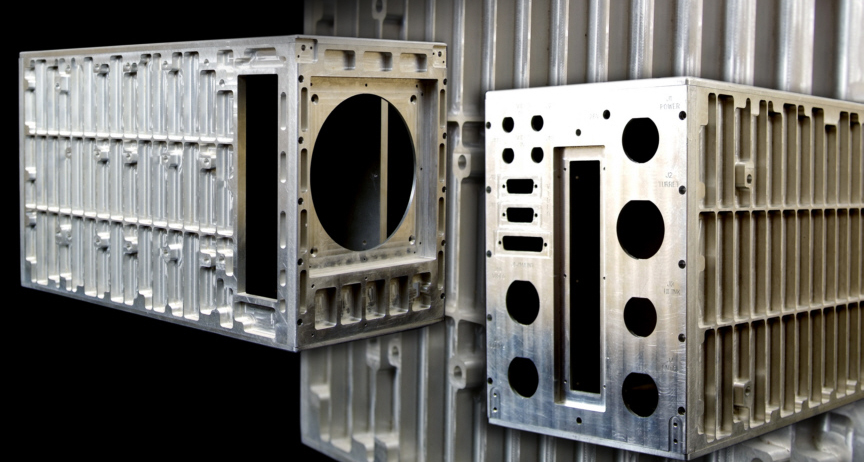

Rugged Systems

PARPRO serves some of the most demanding customers in the world with application-ready systems, and rugged chassis. We have successfully delivered mission critical solutions for many years, reinforcing our position as a high-performance subcontract partner in the defense and aerospace industry. We support multi-faceted rugged computing systems which include printed circuit board assembly (PCBA) and system integration services.

Application Experience:

- Command and Control Systems for Situational Awareness

- Tactical Operator-worn Networking Systems

- Data Acquisition Systems

- Secure Communications Systems

- Interface Control Systems

- Airborne Surveillance Systems

- Inflight Entertainment

- Avionic Flight Systems

PARPRO supports the intricacies specific to the defense and aerospace industry and is certified for ISO-9001:2015, AS-9100D, Nadcap, and ITAR registered.

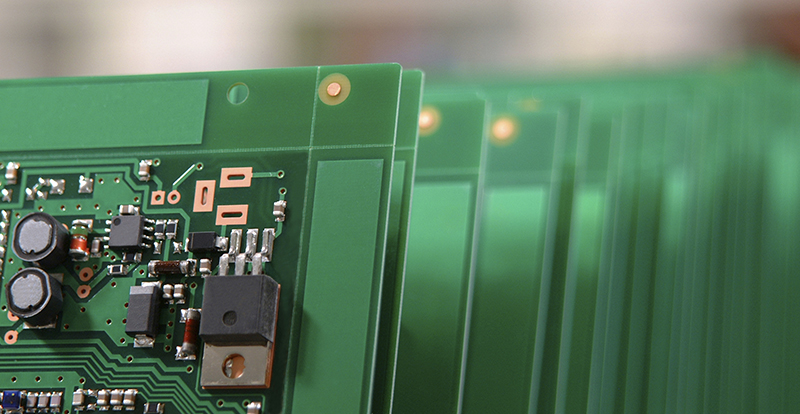

Board-Level Products

PARPRO is a leading-edge supplier of printed circuit boards to the aerospace and defense industries. We specialize in the development of rugged single board computers for the most demanding applications. PARPRO understands the complexities of this industry as well as the many regulations and compliance requirements. PARPRO Technologies is ITAR certified and with the addition of NADCAP for electronics and welding along with our ISO 9001:2015 and AS9100D certifications held by PARPRO Mexico, this provides a unique pre-qualification attractive to customers in the aerospace and defense sectors.

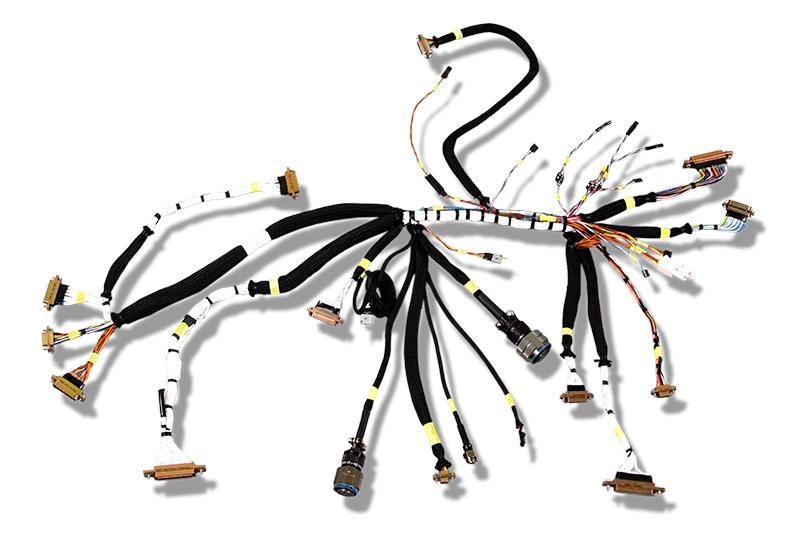

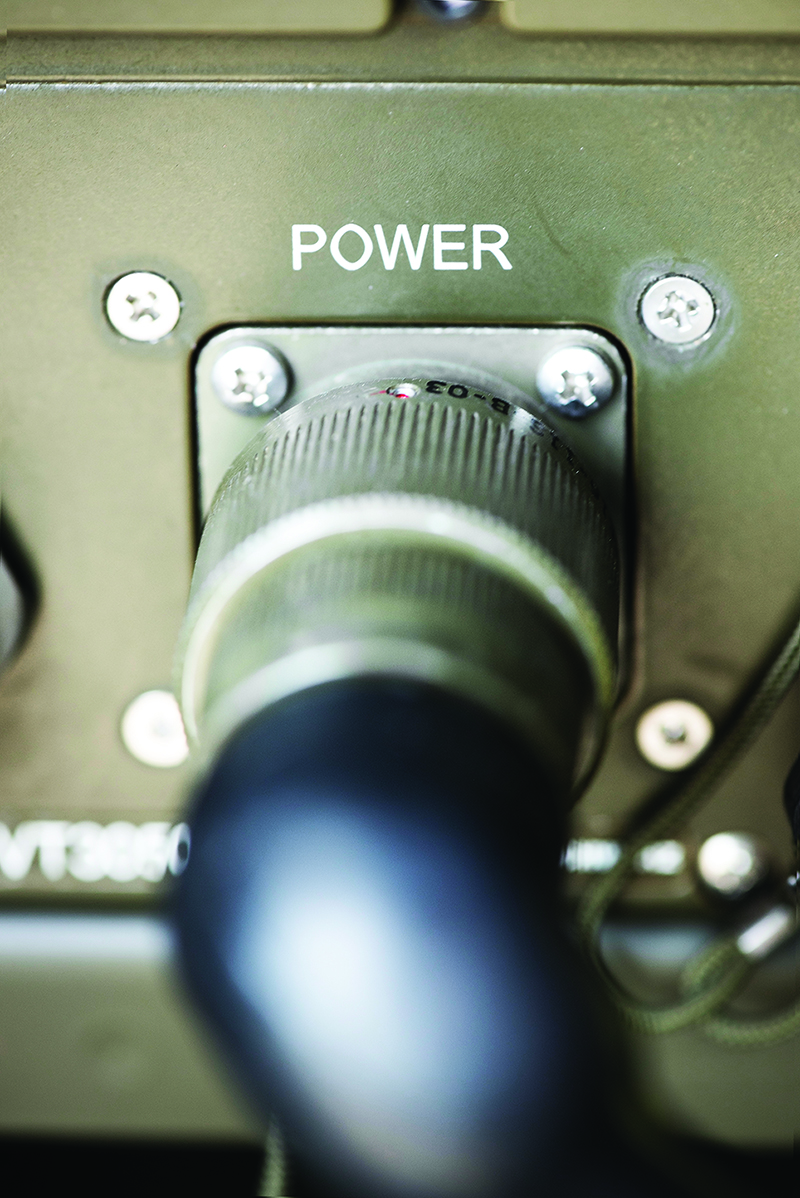

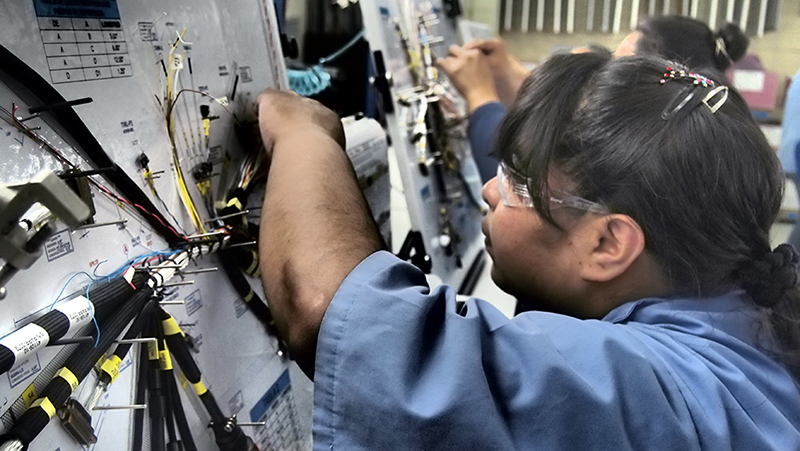

Wire Harness and Cable Assemblies

PARPRO is a leading manufacturer of aerospace and defense cable assemblies and harnesses, as well as tactical cable, and MIL-SPEC connectors. Our cable assemblies are rugged, dependable, and of high signal integrity. They also meet MIL-STD requirements for extreme environmental situations.

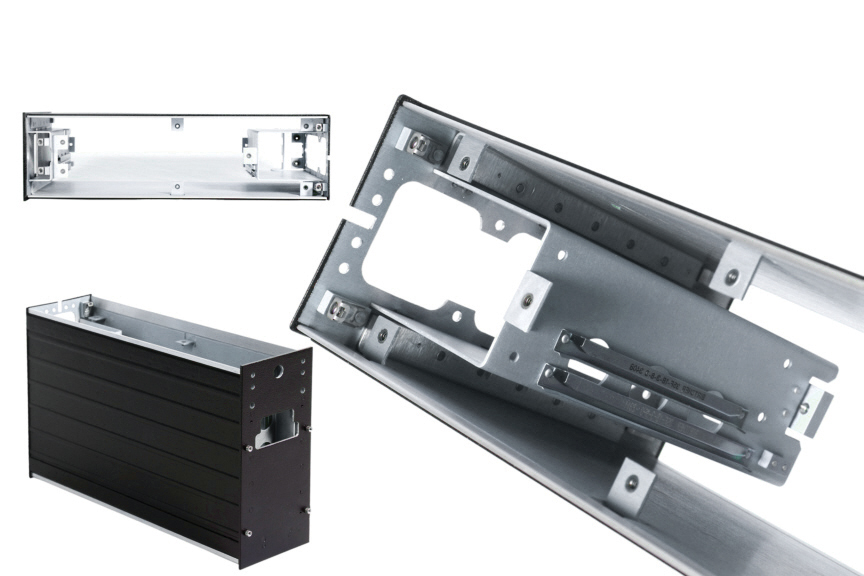

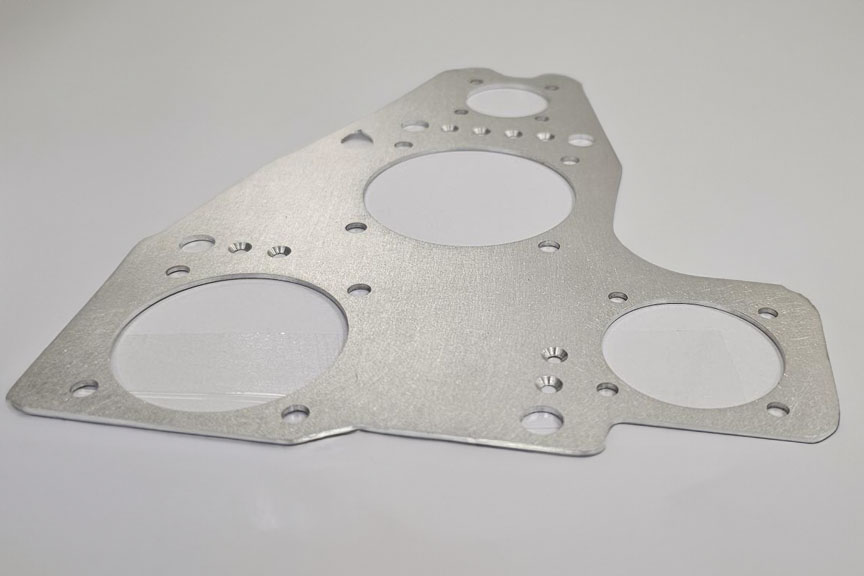

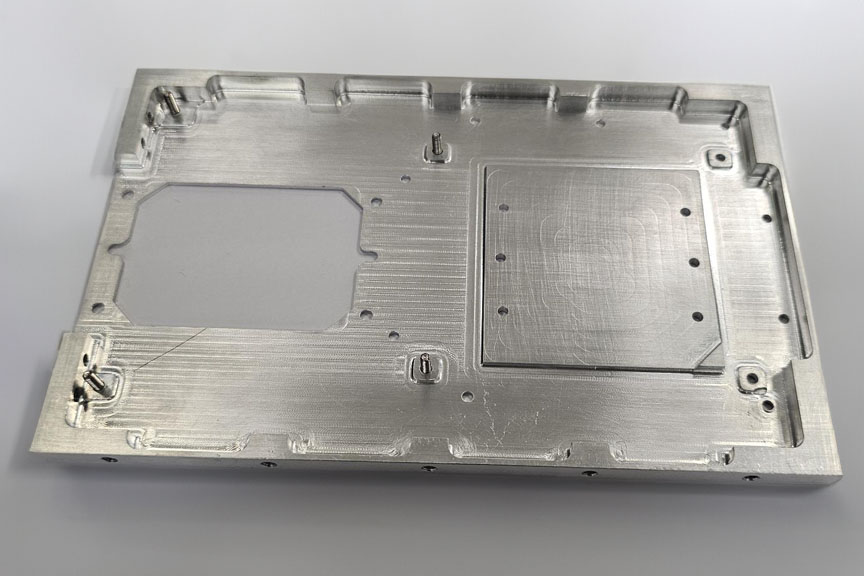

Sheet Metal and Machining

From CNC punch/laser to brake/bend to hardware insertion, to weld/grind and power coating and laminations, PARPRO offers a full range of premium sheet metal fabrication services and metal working capabilities, we utilize state-of the-art equipment and technology along with superior customer service to provide our clients with truly the best in quality.

Featured Case Study

Nadcap Accreditation and What it Means for our Customers

Of the many certifications that contract manufacturing companies hold, the National Aerospace and Defense Contractors Accreditation Program (Nadcap) is one of the most highly coveted. Although Nadcap accreditation was originally established as a means of standardizing quality assurance measures for the aerospace and defense industries, the accreditation has become a symbol of excellence across the board. Nadcap was not officially established until 1990; however, the concept of improving standards in the aerospace industry began in the early 1900’s.