Electro-Mechanical Assemblies

Advanced assembly solutions

custom-built to your exact needs

MANAGE EVERYTHING UNDER ONE ROOF

Leverage One or All of our Capabilities for a Cost-Effective Solution

At PARPRO, we provide complete manufacturing solutions for electro-mechanical systems and sub-assemblies. We provide customers with a highly integrated environment to move from prototype to volume production in dramatically compressed time frames.

PARPRO offers great flexibility to our customers across a diverse range of industries, with superior quality products that meet the unique requirements of their applications. We deliver high-performance solutions, whether the application is quick-service restaurants, medical devices or mission-critical systems, we can meet your unique requirements.

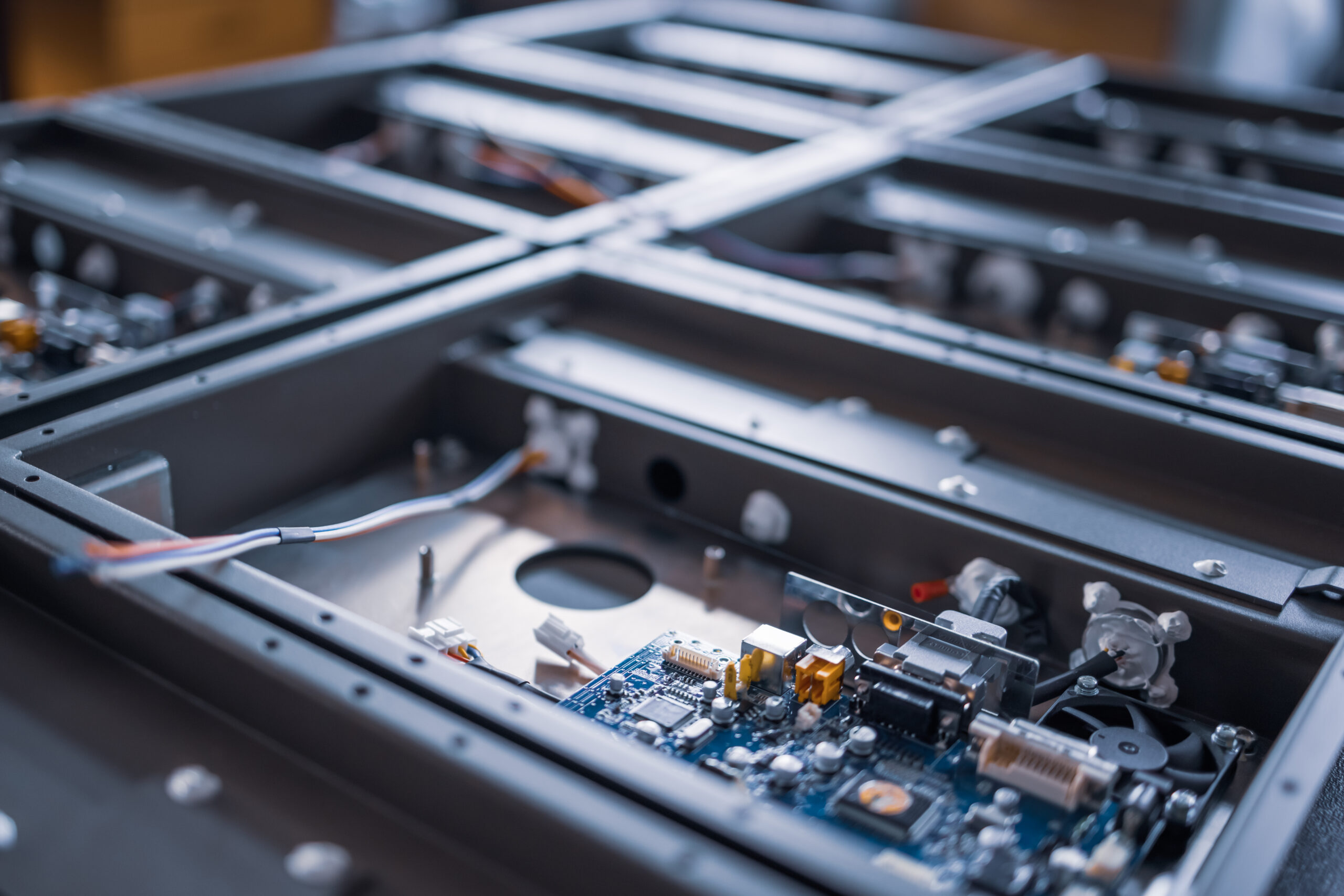

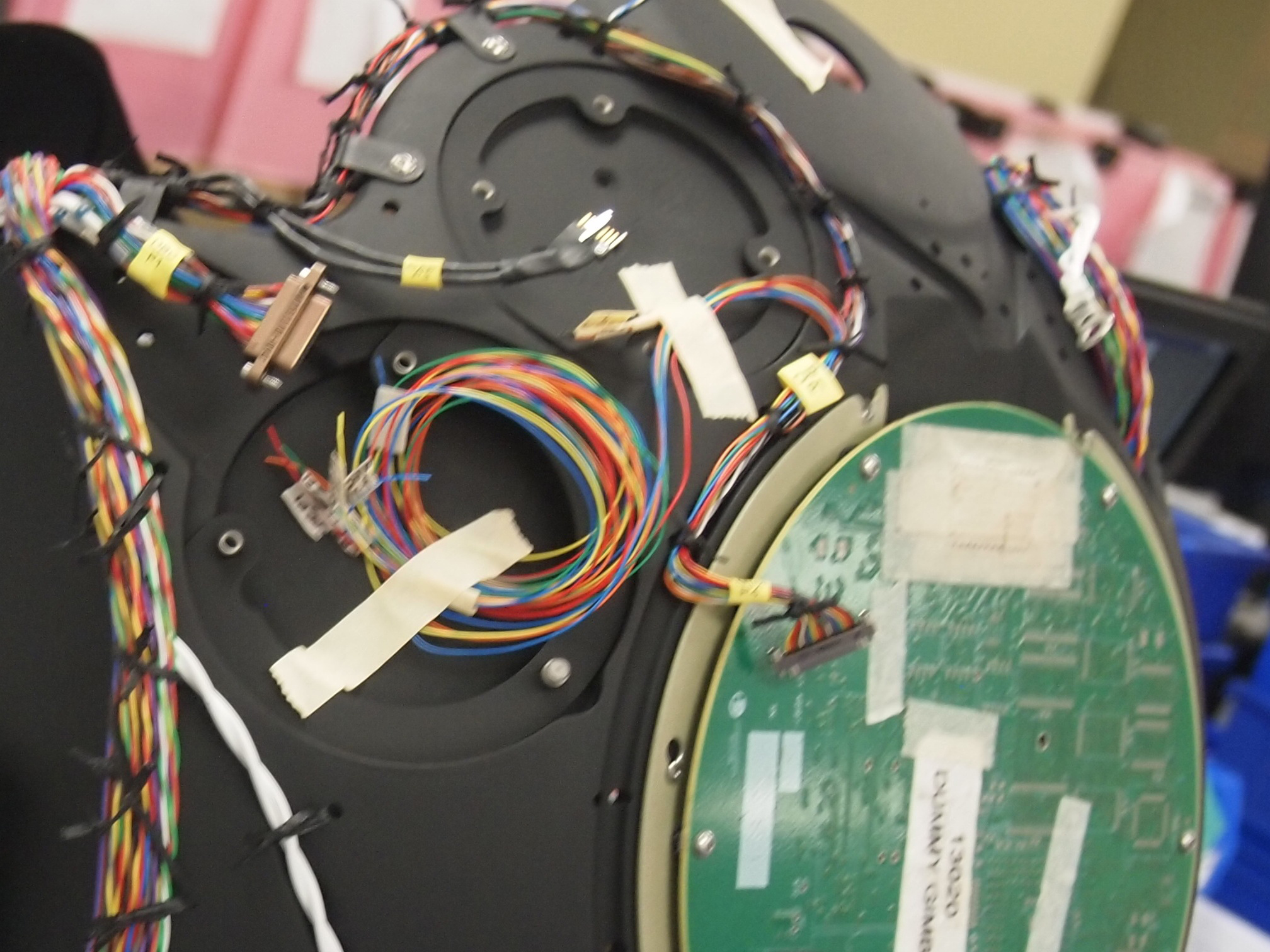

ELECTRO-MECHANICAL ASSEMBLY

Supporting Comprehensive Engineering-Rich Hardware Solutions

PARPRO's electro-mechanical services specialize in the manufacturing of high-quality, high-reliability subsystem and system-level assemblies. Our high-mix environment can support production requirements from low to mid-volume. We offer custom manufacturing and test processes and can work with you on your unique environmental screening.

Our Electro-Mechanical Capabilities

- Integrating multiple PCB assemblies

- Enclosure system configuration

- Sub-chassis assembly and testing

- Cable harness manufacturing

- Cable & wire routing/installation

- Complete mechanical assembly & configuration

- Full system and subsystem integration and testing

- ESS thermal cycling chamber

- More ...