How We Support Communication OEMs

A customized and flexible approach to meet your unique requirements

We Know How to Help

Communications & Networking Hardware Manufacturing Expertise

With the mounting pressure in the technological landscape, companies are transforming their data center into a flexible cloud infrastructure to run demanding applications. The communications industry is moving at a blazing speed with no signs of slowing. 5G, Satellite, RF, IoT and even Radar Systems are driving technology revolutions with increasing demands for mechanical assemblies and hardware to keep up with the software development.

PARPRO supports various products that address voice, data, and video at ever-increasing speeds and is an integral part of this technology shift and is perfectly aligned with high-tech communications companies. As a premier contract manufacturer, PARPRO provides embedded technology solutions for telecommunications, delivering quality complete hardware manufacturing.

Our Expertise

Complete, full-service contract manufacturing services, specializing in the assembly of both mechanical and electronic box build – low to mid-volume production.

Quality & Efficiency

At PARPRO, we are always striving to create more reliable and repeatable manufacturing processes ensuring quality and efficiency are top priority.

Customized Solutions

Decades of Experience

With a rich portfolio of capabilities and 20+ years of manufacturing experience for communications applications, PARPRO has emerged as a proactive solutions partner.

Manufacturing Capabilities

Innovative solutions designed to meet your needs

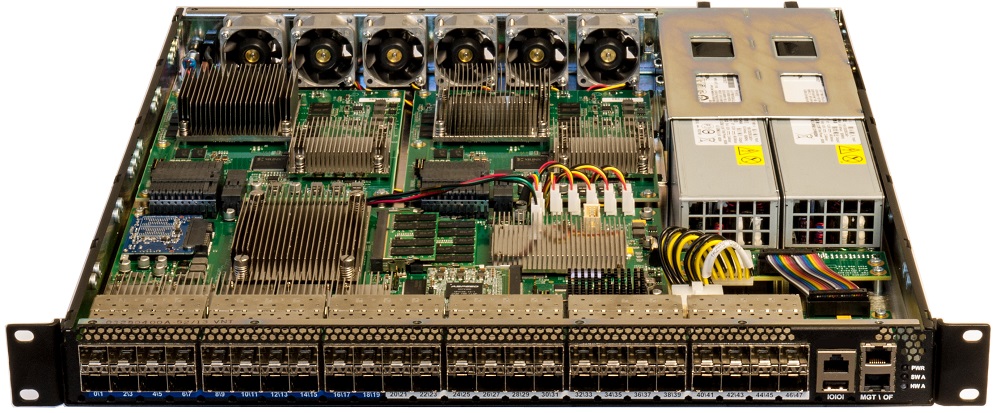

High-Level Assembly

PARPRO supports complex assembly and test operations for sophisticated communications and networking products.

Applications:

- Fiber Optic Communications

- Sensors & Telemetry Devices

- Secure Communications

- Radio Frequency (RF) Applications

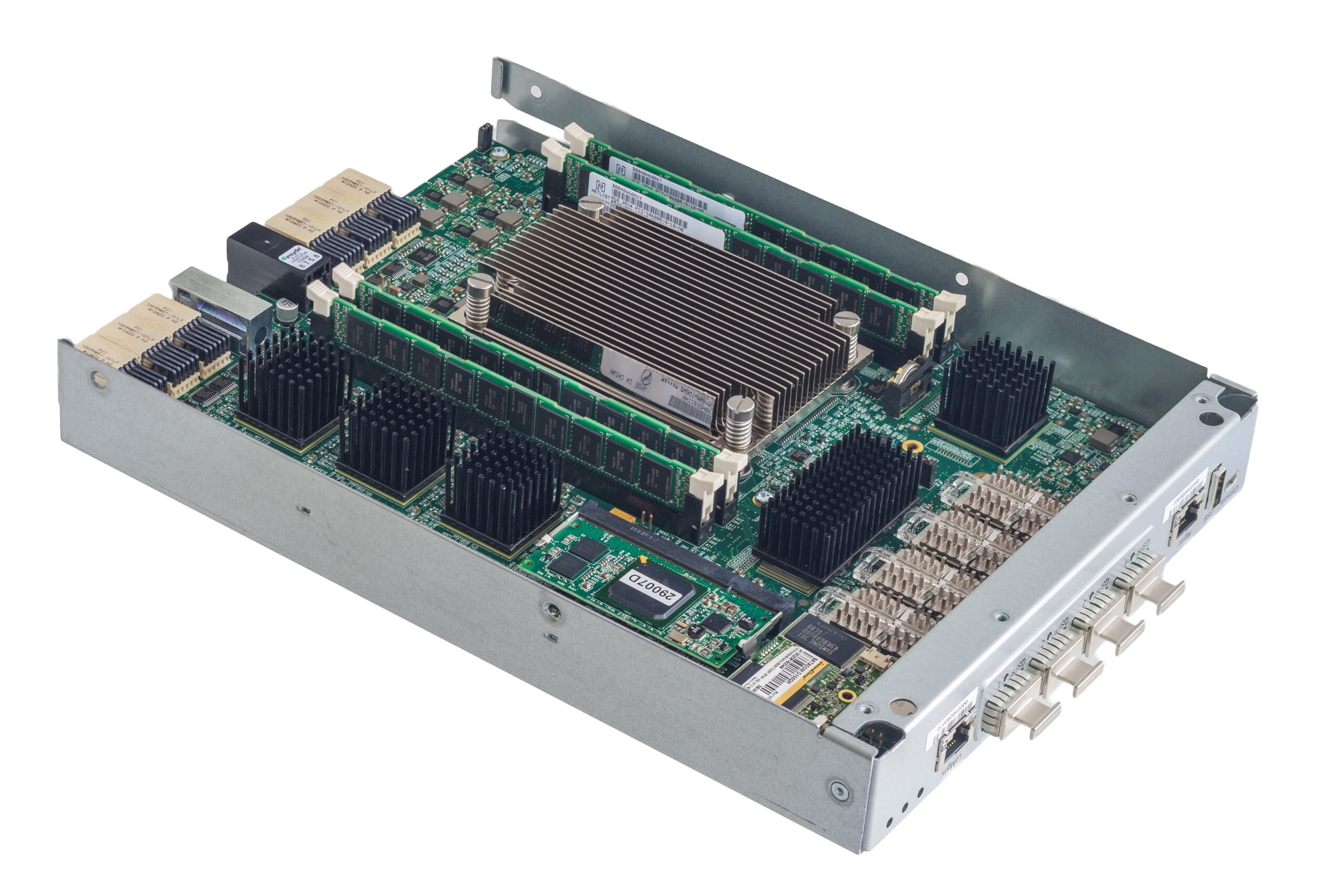

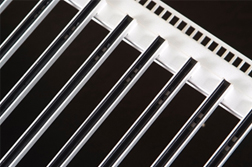

Complex PCBA Manufacturing

PARPRO’s manufacturing environment continually integrates leading-edge printed circuit board assembly (PCBA) equipment and inspection technology.

We offer:

- Highly complex PCBA, full-system assembly, and test

- Support for rugged products and harsh environments

- High-mix and low- to medium-volume production

- Knowledgeable support for regulatory requirements

- Advanced equipment and engineering support

- Experienced supply chain planning for flexible demand environments

- Logistics implementation (Kanban, order fulfillment, etc.)

- Proactive obsolescence materials management

- Flexible manufacturing partner for rapid demand response

- Focus on high quality and reliability

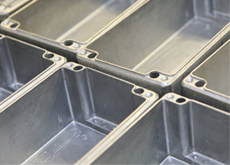

Sheet Metal & Machining

Our custom metal manufacturing processes allow us to manufacture enclosures and cabinets to meet your unique requirements. Whether you need a large control panel for your communications setting, or a rugged enclosure for an outdoor application, we can support your sheet metal and machining needs.

PARPRO can provide engineering assistance for your custom sheet metal enclosures. This could include a complete detailed drawing for spec, enhancement for manufacturability, or a complete DFMA program to ease costs. Our engineering team can work with your design team to develop an ideal solution for your application or provide a fully customized engineered enclosure solution

Featured Story

PARPRO Welcomes Opportunity to Reduce Power Consumption and Waste

UC Irvine’s SMART Industrial Assessment Center visited PARPRO Technologies, Inc. (PTI) to assess opportunities related to Energy Conservation, Waste Reduction, and Productivity Enhancements. A group of trained students from California State University Northridge and UC Irvine, led by Chelsea Choudhary, and experienced faculty, led by Dr. G.P. Li, Director UCI SMART IAC, toured PTI’s Santa Ana factory on February 8th.